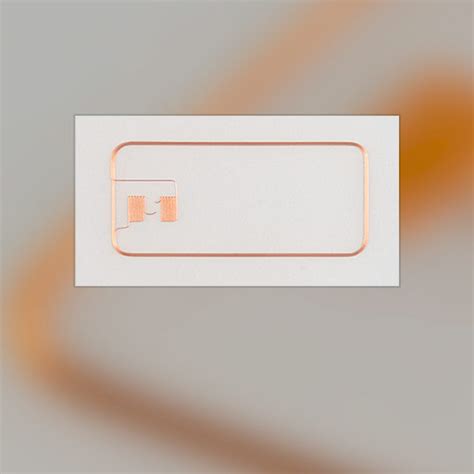

smart card inlay These inlays allow for both contact and contactless interactions, providing users with the convenience of multiple functionalities in a single card. Here we’ll explore what dual interface . Turn on the device and hold a compatible EM4100 card or fob to the side facing the hand grip and click on the “Read” button. The device will then beep if it succeeds, now replace the copied tag with an empty tag and press .

0 · Smart card

1 · Smart Card Inlay Manufacturer

2 · Quality Dual Interface Inlays

3 · Prelaminated Inlays: The Brain of a Smart Card

4 · HID® Prelaminated Inlays

5 · Demystifying the RFID Inlay Manufacturing Process: From

The 2017 NFL Playoff Schedule kicked off on Saturday, Jan. 6, 2018 with two Wild-Card games. In Super Bowl LII, the Philadelphia Eagles defeated the New England Patriots 41-33 at U.S. Bank Stadium .

A good quality prelaminated inlay is the crucial starting point for card makers to manufacture a good end product: a functional smart card. Lamination is one of the essential .

The basis for the smart card is the silicon integrated circuit (IC) chip. It was invented by Robert Noyce at Fairchild Semiconductor in 1959. The invention of the silicon integrated circuit led to the idea of incorporating it onto a plastic card in the late 1960s. The idea of incorporating an integrated circuit chip onto a plastic card was first i.HID Cardlam and HID Skylam are prelaminated inlays for electronic ID cards that provide additional security features and extend the life of polycarbonate cards.These inlays allow for both contact and contactless interactions, providing users with the convenience of multiple functionalities in a single card. Here we’ll explore what dual interface .Discover premium smart card inlays with advanced RFID & NFC technology. Custom solutions for secure access, payments, and identification.

RFID (radio frequency identification) inlays are essential components in RFID technology, used in various applications such as tracking inventory, managing supply chains, . A good quality prelaminated inlay is the crucial starting point for card makers to manufacture a good end product: a functional smart card. Lamination is one of the essential processes in the production of these inlays.

A smart card (SC), chip card, or integrated circuit card (ICC or IC card), is a card used to control access to a resource. It is typically a plastic credit card-sized card with an embedded integrated circuit (IC) chip. [1] Many smart cards include a pattern of metal contacts to electrically connect to the internal chip.HID Cardlam and HID Skylam are prelaminated inlays for electronic ID cards that provide additional security features and extend the life of polycarbonate cards.

These inlays allow for both contact and contactless interactions, providing users with the convenience of multiple functionalities in a single card. Here we’ll explore what dual interface inlays are, their benefits, and how they are transforming the landscape of smart card technology.

Discover premium smart card inlays with advanced RFID & NFC technology. Custom solutions for secure access, payments, and identification. RFID (radio frequency identification) inlays are essential components in RFID technology, used in various applications such as tracking inventory, managing supply chains, and contactless payments. Here's an overview of the RFID inlay manufacturing process.To simplify the production of metal embedded smartcards (that is, metal-veneer cards) we developed the world’s first metal inlay with our companion 8-pin dual-interface chip module. This allows secure card manufacturers to concentrate on .

Prelaminated Smart Card Inlay for Java Card. Smart card inlay is layers of PVC/PET laminated with CPU chip and printed with antenna. It is a great solution to produce Java card. Smart card inlay is the critical and core component of a JAVA card.The smart card module assembly and flip chip inlay manufacturing lines can support a variety of end market applications including financial, banking, government, health, retail, transportation and telecoms.Optilam™ is a smart and sustainable release material that has been specially developed to optimize the manufacturing process of prelaminated inlays dedicated to RFID smart cards. This revolutionary cellulose-based material plays a key protection . A good quality prelaminated inlay is the crucial starting point for card makers to manufacture a good end product: a functional smart card. Lamination is one of the essential processes in the production of these inlays.

A smart card (SC), chip card, or integrated circuit card (ICC or IC card), is a card used to control access to a resource. It is typically a plastic credit card-sized card with an embedded integrated circuit (IC) chip. [1] Many smart cards include a pattern of metal contacts to electrically connect to the internal chip.HID Cardlam and HID Skylam are prelaminated inlays for electronic ID cards that provide additional security features and extend the life of polycarbonate cards.These inlays allow for both contact and contactless interactions, providing users with the convenience of multiple functionalities in a single card. Here we’ll explore what dual interface inlays are, their benefits, and how they are transforming the landscape of smart card technology.Discover premium smart card inlays with advanced RFID & NFC technology. Custom solutions for secure access, payments, and identification.

RFID (radio frequency identification) inlays are essential components in RFID technology, used in various applications such as tracking inventory, managing supply chains, and contactless payments. Here's an overview of the RFID inlay manufacturing process.To simplify the production of metal embedded smartcards (that is, metal-veneer cards) we developed the world’s first metal inlay with our companion 8-pin dual-interface chip module. This allows secure card manufacturers to concentrate on .

Prelaminated Smart Card Inlay for Java Card. Smart card inlay is layers of PVC/PET laminated with CPU chip and printed with antenna. It is a great solution to produce Java card. Smart card inlay is the critical and core component of a JAVA card.The smart card module assembly and flip chip inlay manufacturing lines can support a variety of end market applications including financial, banking, government, health, retail, transportation and telecoms.

Smart card

mifare prox card

$24.90

smart card inlay|Demystifying the RFID Inlay Manufacturing Process: From